Duraynta duritaanku waxay ku dhammaatay dusha sare ee qaabka SPI iyo VDI - dhalaal, dhalaal-maray, matte iyo dhammayn dusha sare ah.

Nuxurka ku xusan qodobkan

- Maxay yihiin dhammays-tirka dusha wax-ku-habaynta cirbadeynta?

- Waa maxay sababta loo isticmaalo dhamaystirka dusha sare ee qaabaynta duritaanka?

- Qalab mudista mudista qeexida dhamaystirka dusha sare

- Dhammaystirka dusha sare ee qaabaynta cirbadeynta SPI

- Dhammaystirka dusha sare ee qaabaynta cirbadeynta VDI

- Sidee loo doortaa dhamaystirka dusha sare ee qaabaynta duritaanka ku habboon?

Maxay yihiin dhammays-tirka dusha wax-ku-habaynta cirbadeynta?

Injection wax ka beddelidda dusha sarewaxay muhiim u tahay nakhshad qayb guulaysata oo loo isticmaalo sababo bilicsan iyo hawlkarnimo qaybaha qaabaynta caagga ah ee alaabta injineernimada.Dhammaystirka dusha sare wuxuu hagaajiyaa muuqaalka iyo dareenka alaabta sida qiimaha la dareemayo iyo tayada alaabadu waxay kordhisaa dhamaystirka dusha sare.

Caagagga (Isha: XR USA Client)

Waa maxay sababta loo isticmaalo dhamaystirka dusha sare ee qaabaynta duritaanka?

Si loo kordhiyo bilicda qayb

Nashqadeeyayaasha qaybta ayaa laga yaabaa inay u isticmaalaan textures ujeedooyin kala duwan oo qurux badan.Dusha sare ee siman ama matte ayaa hagaajinaysa muuqaalkeeda waxayna siinaysaa muuqaal la dhalaalayay.Waxa kale oo ay dabooshaa khaladaadka ka dhasha qaabaynta duritaanka, sida calaamadaha mishiinka qalabka, calamadaha saxanka, xadhkaha alxanka, xadhkaha socodka, iyo calaamadaynta hadhyada.Qaybaha leh tayada sare ee tayada sare leh ayaa aad u soo jiidata macaamiisha marka laga eego dhinaca ganacsiga.

Si loo hagaajiyo shaqada qayb

Marka laga reebo tixgalinta bilicda leh ee doorta dhammaystirka dusha sare ee qaabaynta cirbadeynta, waxa kale oo jira tixgalino la taaban karo oo muhiim ah.

Naqshadu waxay u baahan kartaa xajin adag si ay u shaqeyso ugu fican.Dhammaystirka balaastikada qoraalka ah waxay hagaajiyaan tayada xajinta.Sidaa awgeed daawaynta duritaannada dusha sare leh ayaa inta badan loo isticmaalaa alaabada u adkaysata simbiriirixa.Caaryada la qurxiyey ayaa sidoo kale caawin kara baxsashada gaaska ku xanniban.

Dhammaadka dusha sare ee SPI ee siman waxay keeni kartaa in rinjiga uu dillaaco.Si kastaba ha ahaatee, dusha qallafsan ayaa hubin kara in rinji uu si fiican ugu dheggan yahay shayga la qaabeeyey.Daawaynta dusha sare ee SPI-du waxay sidoo kale kordhisaa xoogga iyo badbaadada qaybta.

Texture waxay leedahay faa'iidooyin dhowr ah, oo ay ku jiraan:

- Qulqulka balaastikada-Xirmooyinkan waxaa laga yaabaa in laga saaro iyadoo lagu darayo dhumucdiisuna waxay kordhinaysaa xoogga iyo sifooyinka aan sibxanayn.

- Qabashada la hagaajiyay-Ku-daridda nuxurka qaybta waxay fududaynaysaa maaraynta, kordhinta faa'iidada iyo badbaadada codsiyada gaarka ah.

- adhesion rinjiga-Rinjigu wuxuu si adag ugu dheggan yahay shay la qurxiyey inta lagu jiro qaabaynta soo socota.

- Samaynta gooyn hoose-Haddii aad haysatid qayb aan si joogto ah ugu imanayn badhkii dhaqaaqa ee caaryada, qoraalka dushiisa waxa laga yaabaa inay ku siiso waxyaabaha lagama maarmaanka ah.ll.

Qalab mudista mudista qeexida dhamaystirka dusha sare

Habka ugu badan ee lagu qeexo meelaha duridda wax lagu sameeyo waa iyadoo la isticmaalayoPIA (ama SPI), VDIiyoFarsamada caaryadaheerarka.Qalab-sameeyayaasha caaryada cirbadaha, soosaarayaasha iyo injineerada naqshadaynta adduunka oo dhan waxay aqoonsan yihiin saddexdan heerar iyo heerarka PIA waa kuwo aad u caan ah oo si weyn loogu yaqaanno "darajooyinka SPI".

Dhammaadka dhalaalaya - Fasalka A - Dhammaadka dheeman

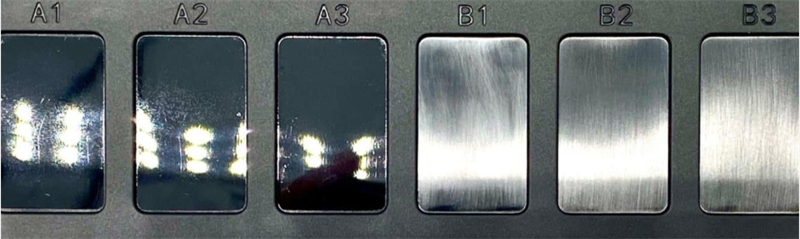

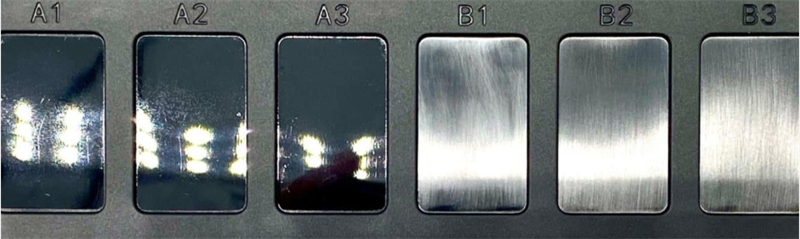

(SPI-AB Durida-qaabaynta dusha sare ee dhammayn)

Dhammaadka darajadan "A" waa siman yihiin, dhalaal badan yihiin, iyo kuwa ugu qaalisan.Darajooyinkani waxay u baahan yihiin qalab adag oo bir ah, kuwaas oo lagu dhajiyay iyadoo la isticmaalayo darajooyin kala duwan oo dheeman ah.Sababtoo ah koollada miraha-fiican iyo habka toosinta wareegga jihada ee random, ma yeelan doonto muuqaal cad oo kala firdhinaya fallaadhaha iftiinka, taasoo siinaysa dhammaystir aad u dhalaalaya.Kuwan waxa kale oo loo yaqaan "Diamond finish" ama "Buff finish" ama "A finish"

| dhame | Heerka SPI | Habka Dhameystirka | Roughness dusha sare (Ra Value) |

| Dhammays Qurux Badan | A1 | 6000 Grit diamond buff | 0.012 ilaa 0.025 |

| Dhammays Qurux Badan | A2 | 3000 Grit diamond buff | 0.025 ilaa 0.05 |

| Dhammaystirka dhalaalka caadiga ah | A3 | 1200 Grit diamond buff | 0.05 ilaa o.1 |

Darajooyinka gloss SPI waxay ku habboon yihiin alaabooyinka leh dusha sare ee siman sababo la isku qurxiyo iyo kuwo shaqeynaya.Tusaale ahaan, A2 waa dhamaystirka dheeman ee ugu caansan ee loo isticmaalo warshadaha, taasoo keentay qaybo wanaagsan oo muuqaal ah oo si fiican loo sii daayo.Intaa waxaa dheer, dhamaystirka dusha sare ee "A" waxaa loo isticmaalaa qaybaha indhaha sida muraayadaha, muraayadaha, iyo fiilooyinka.

Dhammaystirka dhaldhalaalka - Fasalka B

(Jaantuska 2.SPI-AB Durida-qaabaynta dusha sare ee dhammayn)

Dhammaystirkan semi-gloss-ka ah ayaa ku fiican in meesha laga saaro mishiinada, samaynta, iyo calaamadaynta qalabaynta oo leh kharash qalabayn macquul ah.Dhammaystirkan dusha sare waxaa lagu soo saaraa darajooyin kala duwan oo waraaqo ciid ah oo lagu dabaqay dhaqdhaqaaq toosan, iyadoo la siinayo qaab toosan sida ku cad shaxanka 2.

| dhame | Heerka SPI | Habka Dhameystirka | Roughness dusha sare (Ra Value) |

| Dhammaadka Semi dhalaalka Fine | B1 | 600 Waraaqo Jaranjaro ah | 0.05 ilaa 0.1 |

| Dhammaadka Semi dhalaalka dhexdhexaadka ah | B2 | 400 oo warqad ah | 0.1 ilaa 0.15 |

| Dhammaystirka Emi Glossy Caadiga ah | B3 | 320 warqad xariijimo ah | 0.28 ilaa o.32 |

SPI(B 1-3) Dhammaystirka dusha sare ee dhaldhalaalka ah waxay siin doontaa muuqaal muuqaal wanaagsan waxayna meesha ka saaraysaa calaamadaha qalabka caaryada.Kuwaas waxaa badanaa loo isticmaalaa qaybo aan ahayn qayb qurxin ama muuqaal muhiim ah oo ka mid ah alaabta.

Matte dhammayn - Fasalka C

Kuwani waa kuwa ugu dhaqaalaha badan uguna caansan dusha sare ee la dhammeeyo, oo la sifeeyay iyadoo la adeegsanayo budada dhagaxa ah.Mararka qaarkood waxaa loogu yeeraa dhameynta dhagaxa, waxay bixisaa siideyn wanaagsan waxayna caawisaa qarinta calaamadaha mashiinka.Fasalka C sidoo kale waa tallaabada koowaad ee darajooyinka A iyo B ee dhammayntooda.

| dhame | Heerka SPI | Habka Dhameystirka | Roughness dusha sare (Ra Value) |

| Dhammaystirka matte dhexdhexaad ah | C1 | 600 Grit Stone | 0.35 ilaa 0.4 |

| Dhammaystirka matte dhexdhexaad ah | C2 | 400 oo warqad ah | 0.45 ilaa 0.55 |

| Dhammaystirka matte caadiga ah | C3 | 320 warqad xariijimo ah | 0.63 ilaa 0.70 |

Dhamaystirka qoraalka - Fasalka D

Waxay siisaa qaybta muuqaal muuqaal ah oo qurux badan oo macquul ah waxaana si ballaaran loogu isticmaalaa qaybaha warshadaha iyo alaabta macaamiisha.Kuwani waxay ku habboon yihiin qaybo aan lahayn shuruudo muuqaal gaar ah.

| dhame | Heerka SPI | Habka Dhameystirka | Roughness dusha sare (Ra Value) |

| Dhammaadka qoraalka Satin | D1 | 600 oo dhagax ka hor tus quraarad qarax engegan #11 | 0.8 ilaa 1.0 |

| Dhammaystirka Qoraalka Qalalan | D2 | 400 oo dhagax ah ka hor dhalada qaraxa engegan #240 oxide | 1.0 ilaa 2.8 |

| Dhammaystirka qoraalka qalafsan | D3 | 320 dhagax ka hor qaraxa engegan #24 oxide | 3.2 ilaa 18.0 |

Qofna waligiis ma sheegin in naqshadaynta iyo soo saarista qaybaha la qaabeeyey ay fududaayeen.Hadafkayagu waa inaan si dhakhso leh oo tayo leh kuugu soo marno.

Dhammaystirka dusha sare ee qaabaynta cirbadeynta VDI

Dhammaystirka dusha sare ee VDI 3400 (badanaa loo yaqaan VDI dusha sare) waxaa loola jeedaa heerka texture texture ee uu dejiyay Verein Deutscher Ingenieure (VDI), Bulshada Injineerada Jarmalka.Dhamaystirka dusha sare ee VDI 3400 waxaa inta badan lagu farsameeyaa Mashiinka Soo saarista Korontada (EDM) marka la farsameynayo caaryada.Waxa kale oo lagu samayn karaa habka qoraalka dhaqameed (sida SPI).In kasta oo heerarka ay dejiyeen bulshada Injineerada Jarmalka, haddana waxaa caadi ahaan loo adeegsadaa aaladaha sameeya dhammaan, oo ay ku jiraan Waqooyiga Ameerika, Yurub, iyo Aasiya.

Qiimaha VDI waxay ku salaysan yihiin qallafsanaanta dusha sare.Laga soo bilaabo sawirka, waxaan aragnaa muuqaalo kala duwan oo ka mid ah dhamaystirka dusha sare oo leh qiime kala duwan ee qallafsanaanta dusha sare.

| Qiimaha VDI | Sharaxaada | Codsiyada | Dusha oo qallafsan (Ra µm) |

| 12 | 600 Dhagax | Qaybaha boodhka hoose | 0.40 |

| 15 | 400 Dhagax | Qaybaha boodhka hoose | 0.56 |

| 18 | Qurxinta Qurxinta Qalalan | Satin dhammayn | 0.80 |

| 21 | Qarax Qalalan # 240 Oxide | dhammayn caajis ah | 1.12 |

| 24 | Qarax Qalalan # 240 Oxide | dhammayn caajis ah | 1.60 |

| 27 | Qarax Qalalan # 240 Oxide | dhammayn caajis ah | 2.24 |

| 30 | Qarax Qalalan # 24 Oxide | dhammayn caajis ah | 3.15 |

| 33 | Qarax Qalalan # 24 Oxide | dhammayn caajis ah | 4.50 |

| 36 | Qarax Qalalan # 24 Oxide | dhammayn caajis ah | 6.30 |

| 39 | Qarax Qalalan # 24 Oxide | dhammayn caajis ah | 9.00 |

| 42 | Qarax Qalalan # 24 Oxide | dhammayn caajis ah | 12.50 |

| 45 | Qarax Qalalan # 24 Oxide | dhammayn caajis ah | 18.00 |

Gabagabo

Marka laga reebo labada qaybood ee dhammaystirka wax-qaabaynta durida, darajada SPI A iyo B waxaa loo arkaa inay yihiin kuwa ugu fudud oo leh qallafsanaan korka oo aad u hooseeya waana qaali.Halka, marka laga eego dhinaca qallafsanaanta dusha sare, VDI 12, VDI-ga ugu tayada sarreeya, uu la mid yahay darajada SPI C.

Qofna waligiis ma sheegin in naqshadaynta iyo soo saarista qaybaha la qaabeeyey ay fududaayeen.Hadafkayagu waa inaan si dhakhso leh oo tayo leh kuugu soo marno.

Sidee loo doortaa dhamaystirka dusha sare ee qaabaynta duritaanka ku habboon?

Dooro dhamaystirka dusha sare ee qaabaynta cirbadeynta adoo tixgelinaya shaqada qayb, walxaha la isticmaalo, iyo shuruudaha muuqaalka.Inta badan walxaha caagga ah ee la isku duro ee caadiga ah waxay yeelan karaan noocyo kala duwan oo dusha sare ah.

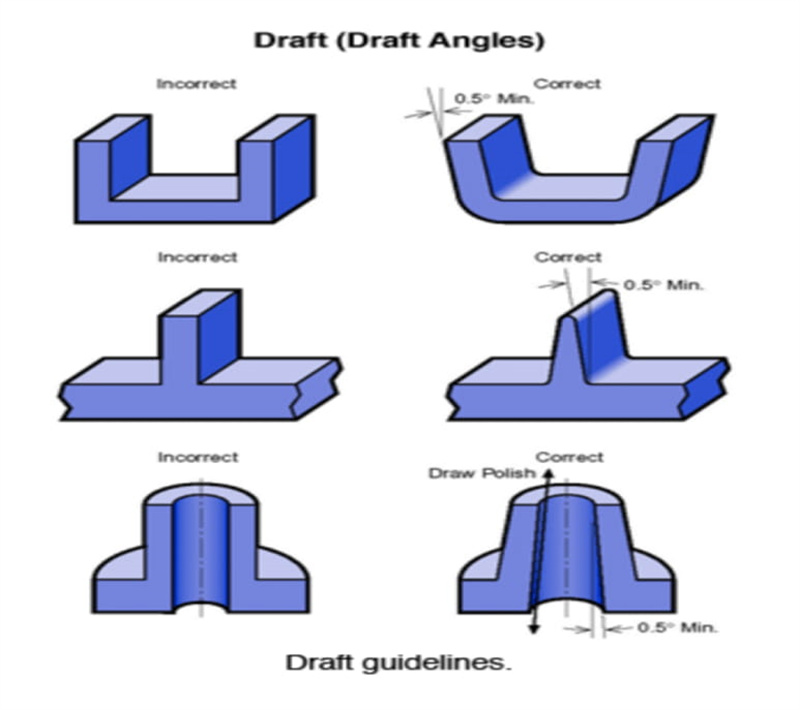

Xulashada dhamaystirka dusha sare waa in lagu dhisaa qaabka hore ee naqshadaynta naqshadaynta alaabta sababtoo ah dusha sare ayaa tilmaamaya xulashada alaabta iyo xagasha qabyada ah, oo saameynaysa kharashka qalabka.Tusaale ahaan, koorsada ama dhamaystirka qoraalka ah wuxuu u baahan yahay xagal qabyo ah oo muhiim ah si qaybta looga saaro caaryada.

Haddaba waa maxay arrimaha ugu muhiimsan ee la tixgelinayo marka la dooranayo dhammaadka dusha sare ee caagadaha wax lagu duray?

Dhammaadka dhaldhalaalka Fasalka A (Isha:XR USA Macmiilka)

Qiimaha qalabka

Dhammaystirka dusha sare iyo maaddada si weyn ayey u saameeyaan naqshadaynta qalabka iyo qiimaha, markaa ka fiirso oo qiimee shaqada marka la eego dusha hore ee naqshadaynta qaabdhismeedka.Haddii dusha sare ee dusha sare uu muhiim u yahay shaqeyntiisa, tixgeli dhamaystirka dusha sare ee marxaladaha fikradda ee naqshadeynta alaabta.

Qaybo badan oo ka mid ah habka qaabaynta duritaanka ayaa si toos ah loo sameeyay, laakiin sifaynta ayaa ka reeban.Kaliya waa qaabka ugu fudud oo si toos ah loo turxaan bixin karo.Booliisku hadda waxay haystaan qalab iyo agab ka wanaagsan oo ay ku shaqeeyaan, laakiin geeddi-socodku weli waa mid xoog badan.

xagal qabyo ah

Qaybaha badankoodu waxay u baahan yihiin xagal qabyo ah oo ah 1½ ilaa 2 darajo

Tani waa qaanuunka suulka ee quseeya qaybaha la qurxiyey ee qoto dheer ilaa 2 inji.Cabirkan, qabyo ah ilaa 1½ darajo ayaa ku filan in si fudud looga sii daayo qaybo ka mid ah caaryada.Tani waxay kaa caawineysaa inaad ka hortagto waxyeelada qaybaha marka walxaha heerkulku hoos u dhaco.

Qalabka caaryada

Qalabka caaryada ayaa si weyn u saameeya simanaanta dusha sare ee qaabeynta cirbadeynta.Caaryada waxaa laga yaabaa in laga sameeyo biro kala duwan, inkastoo birta iyo aluminium ay yihiin kuwa ugu caansan.Saamaynta labadan biraha ah ee qaybaha balaastigga ah ayaa aad u kala duwan.

Guud ahaan, qalabka adag ee birta ah waxay soo saari kartaa dhamaystir caag ah oo siman marka loo eego qalabka aluminiumka.Markaa ka fiirso caaryada birta ah haddii gabalku leeyahay hawl bilicsan oo u baahan heer hoose oo qallafsanaanta dusha sare.

Qalabka wax lagu dhejiyo

Balaagyo kala duwan oo wax lagu duri karo ayaa diyaar ah si ay u daboosho dhammaan noocyada qaybaha iyo shaqooyinka.Si kastaba ha ahaatee, balaastikada oo dhan ma gaari karaan dhammayn duritaan oo isku mid ah.Qaar ka mid ah polymers-ka ayaa ku habboon dhamaystirka siman, halka kuwa kalena ay ku habboon yihiin in la isku qurxiyo oo loogu talagalay dusha sare ee tayada leh.

Kiimikada iyo tayada jireed waxay ku kala duwan yihiin qalabka wax lagu qaabeeyo ee duritaanka.Heerkulka dhalaalida, tusaale ahaan, waa arrin muhiim u ah awoodda walaxda si ay u bixiso tayada dusha sare ee gaarka ah.Waxyaabaha lagu daro waxay sidoo kale saameyn ku leeyihiin natiijada badeecada la dhammeeyay.Natiijo ahaan, waa muhiim in la qiimeeyo walxaha kala duwan ka hor inta aan la go'aansanin qaabka dusha sare.

Intaa waxaa dheer, walxaha lagu daro sida buuxinta iyo midabada ayaa laga yaabaa inay saameyn ku yeeshaan dhamaadka shay la qaabeeyey.Jaantusyada qaybta xigta waxay muujinayaan ku-dhaqanka maaddooyinka qaabaynta duritaanka ee kala duwan ee SPI.

Ku habboonaanta walxaha darajada SPI-A ee dhammaystirka dusha sare

| Qalab | A-1 | A-2 | A-3 |

| ABS | Celcelis ahaan | Celcelis ahaan | Wacan |

| Polypropylene (PP) | Laguma talin | Celcelis ahaan | Celcelis ahaan |

| Polystyrene (PS) | Celcelis ahaan | Celcelis ahaan | Wacan |

| HDPE | Laguma talin | Celcelis ahaan | Celcelis ahaan |

| Nayloon | Celcelis ahaan | Celcelis ahaan | Wacan |

| Polycarbonate (PC) | Celcelis ahaan | Wacan | Aad u fiican |

| Polyurethane (TPU) | Laguma talin | Laguma talin | Laguma talin |

| Acrylic | Aad u fiican | Aad u fiican | Aad u fiican |

Ku habboonaanta walxaha ee darajada SPI-B ee dhammayntooda

| Qalab | B-1 | B-2 | B-3 |

| ABS | Wacan | Wacan | Aad u fiican |

| Polypropylene (PP) | Wacan | Wacan | Aad u fiican |

| Polystyrene (PS) | Aad u fiican | Aad u fiican | Aad u fiican |

| HDPE | Wacan | Wacan | Aad u fiican |

| Nayloon | Wacan | Aad u fiican | Aad u fiican |

| Polycarbonate (PC) | Wacan | Wacan | Celcelis ahaan |

| Polyurethane (TPU) | Laguma talin | Celcelis ahaan | Celcelis ahaan |

| Acrylic | Wacan | Wacan | Wacan |

Ku habboonaanta walxaha ee Fasalka SPI-C ee dhammaystirka dusha sare

| Qalab | C-1 | C-2 | C-3 |

| ABS | Aad u fiican | Aad u fiican | Aad u fiican |

| Polypropylene (PP) | Aad u fiican | Aad u fiican | Aad u fiican |

| Polystyrene (PS) | Aad u fiican | Aad u fiican | Aad u fiican |

| HDPE | Aad u fiican | Aad u fiican | Aad u fiican |

| Nayloon | Aad u fiican | Aad u fiican | Aad u fiican |

| Polycarbonate (PC) | Celcelis ahaan | Laguma talin | Laguma talin |

| Polyurethane (TPU) | Wacan | Wacan | Wacan |

| Acrylic | Wacan | Wacan | Wacan |

Ku habboonaanta walxaha darajada SPI-D ee dhammaystirka dusha sare

| Qalab | D-1 | D-2 | D-3 |

| ABS | Aad u fiican | Aad u fiican | Wacan |

| Polypropylene (PP) | Aad u fiican | Aad u fiican | Aad u fiican |

| Polystyrene (PS) | Aad u fiican | Aad u fiican | Wacan |

| HDPE | Aad u fiican | Aad u fiican | Aad u fiican |

| Nayloon | Aad u fiican | Aad u fiican | Wacan |

| Polycarbonate (PC) | Aad u fiican | Laguma talin | Laguma talin |

| Polyurethane (TPU) | Aad u fiican | Aad u fiican | Wacan |

| Acrylic | Celcelis ahaan | Celcelis ahaan | Celcelis ahaan |

Halbeegyada qaabaynta

Xawaaraha cirbadeynta iyo heerkulku waxay saameeyaan dhammaadka dusha dhowr sababood dartood.Markaad isku dartid xawaaraha duritaanka degdega ah iyo heerkul sare oo dhalaal ama caaryar ah, natiijadu waxay kor u qaadi doontaa dhalaalka ama simanaanta dusha qaybta.Dhab ahaantii, xawliga duritaanka degdega ah wuxuu hagaajiyaa dhalaalka guud iyo simanaanta.Intaa waxaa dheer, buuxinta degdega ah ee daloolka caaryada waxay soo saari kartaa khadadka alxanka oo aan muuqan iyo tayada bilicda ee qaybtaada.

Go'aaminta qaybta dusha sare ee qaybta waa tixgalin muhiim ah oo ku saabsan horumarinta alaabta guud waana in laga fekeraa inta lagu jiro habka naqshadaynta si loo gaaro natiijooyinka la rabo.Ma ka fikirtay dhamaadka isticmaalka qaybtaada qaabaysan ee duritaanka?

U ogolow Xiamen Ruicheng inuu kaa caawiyo inaad go'aansato dhamaystirka dusha sare ee hagaajinaya bilicda iyo shaqeynta qaybtaada.

Waqtiga boostada: Meey-22-2023